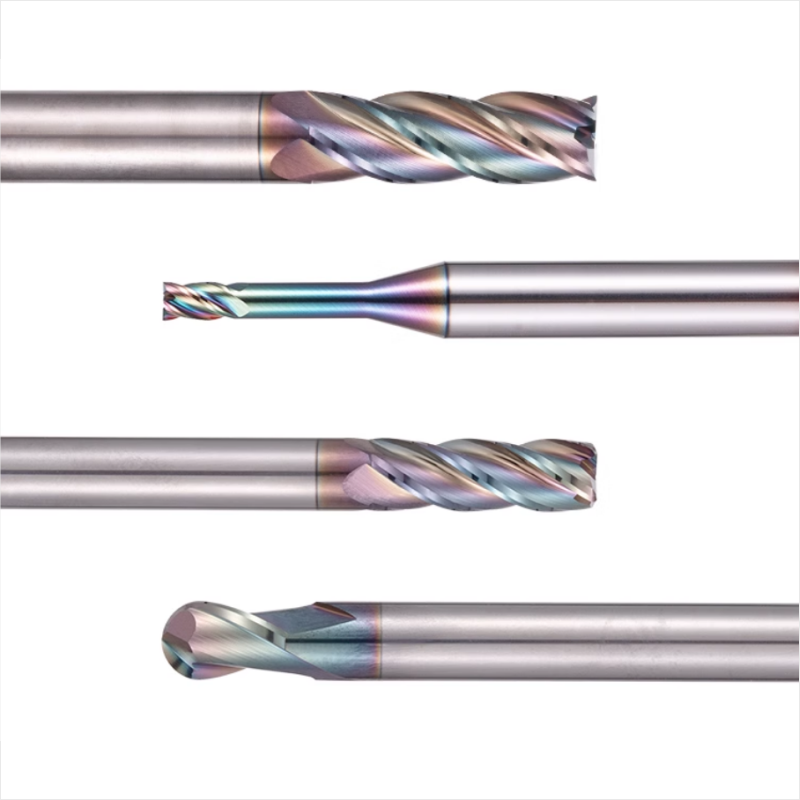

High Precision Dedicated Carbide End Mill Small Diameter Copper Electrodes High Surface Finish Milling Cutter

Detail Information

| Product Name: | Carbide End Mill | Model: | Square endmill for Copper Electrodes |

|---|---|---|---|

| Material: | HRC55 Tungsten Steel carbide Japan | Workpiece: | Copper Electrodes/ Copper |

| Usage: | Milling | Coating: | AlTiN /Nano coating/DLC coating |

| HRC: | HRC55 | Feature: | High Wear-resistance /Few BUE/Long Life |

| Application: | CNC Machining | Package: | 1pcs/Box |

| Highlight: |

carbide End Mill,High quality End Mill for Copper Electrodes,Durable endmill for Copper Electrodes,Long Life and BUE free end mill; |

||

Product Description

High Precision Dedicated Carbide End Mill Small Diameter Copper Electrodes (Red Purple) High Surface Finish Milling Cutter

Features:

- Specific tools for Copper Electrodes use only ;

- Imported high-quality raw materials from Japan;

- High precision at 0.001mm and hardness;

- High quality coating material from Germany;

- Durable and Highly wear-resistant;

- High processing efficiency;

- Stable performance;

- Good impact resistance;

- 1.Specific tools, to be used for the processing of Copper Electrodes,Copper use ;

- 2.Bring good surface roughness after processing;

- 3.With highly heat-resistant AlTiN coating or other quality coating, can be used for high-speed and high finish processing;

- 4.High toughness, using grain-sized carbon tungsten as the raw material;

- 5.Help to increase the smoothness, reduce the friction coefficient,and improve the milling efficiency, thus save more production time;

Important Notes:

-

- To be made according to your special demands;

- 100% Quality Warranty ;

- 100% Inspection under Famous equipments;

- Fast Delivery in 2-3 days;

- Over 30 years experience in precision cutting tools;

- With 30 years experience technician and R&D center in Japan;

- With Branches in Singapore / Japan / China / USA / Mexico / Brazil / UK / Philippines / Malaysia / Turkey/ Argentina;

- Product positioning: High Quality + Reasonable Price.

- Shipping By Fedex /DHL /UPS;

Note:

- If the following carbide end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 1F, 2F, 3F, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

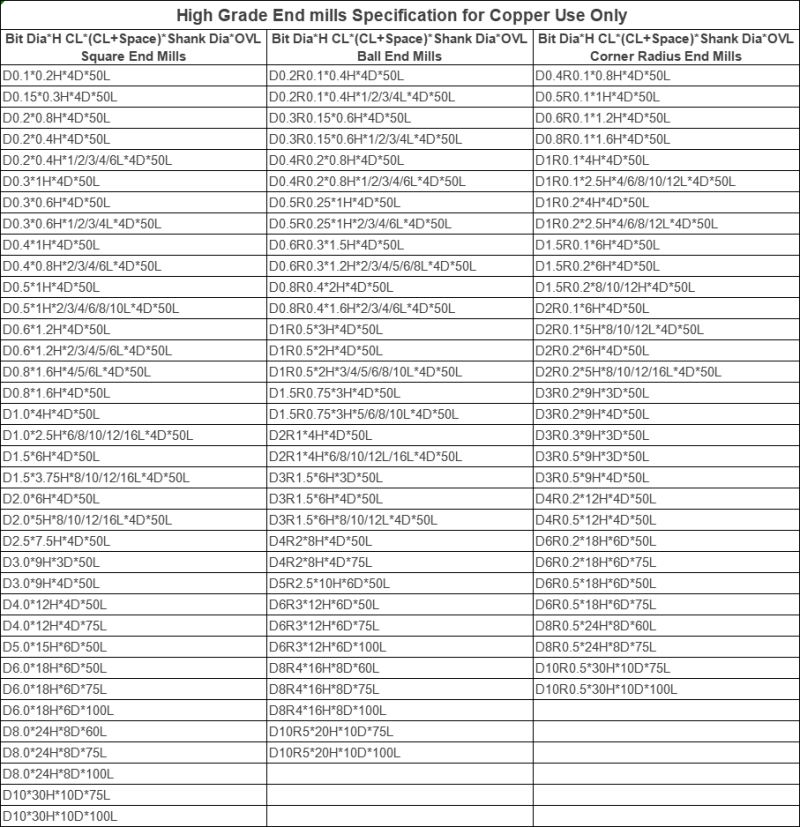

| High Grade End mills Specification for Copper Electrodes Use Only | ||

| Bit Dia*H CL*(CL+Space)*Shank Dia*OVL Square End Mills | Bit Dia*H CL*(CL+Space)*Shank Dia*OVL Ball End Mills | Bit Dia*H CL*(CL+Space)*Shank Dia*OVL Corner Radius End Mills |

| D0.1*0.2H*4D*50L | D0.2R0.1*0.4H*4D*50L | D0.4R0.1*0.8H*4D*50L |

| D0.15*0.3H*4D*50L | D0.2R0.1*0.4H*1/2/3/4L*4D*50L | D0.5R0.1*1H*4D*50L |

| D0.2*0.8H*4D*50L | D0.3R0.15*0.6H*4D*50L | D0.6R0.1*1.2H*4D*50L |

| D0.2*0.4H*4D*50L | D0.3R0.15*0.6H*1/2/3/4L*4D*50L | D0.8R0.1*1.6H*4D*50L |

| D0.2*0.4H*1/2/3/4/6L*4D*50L | D0.4R0.2*0.8H*4D*50L | D1R0.1*4H*4D*50L |

| D0.3*1H*4D*50L | D0.4R0.2*0.8H*1/2/3/4/6L*4D*50L | D1R0.1*2.5H*4/6/8/10/12L*4D*50L |

| D0.3*0.6H*4D*50L | D0.5R0.25*1H*4D*50L | D1R0.2*4H*4D*50L |

| D0.3*0.6H*1/2/3/4L*4D*50L | D0.5R0.25*1H*2/3/4/6L*4D*50L | D1R0.2*2.5H*4/6/8/12L*4D*50L |

| D0.4*1H*4D*50L | D0.6R0.3*1.5H*4D*50L | D1.5R0.1*6H*4D*50L |

| D0.4*0.8H*2/3/4/6L*4D*50L | D0.6R0.3*1.2H*2/3/4/5/6/8L*4D*50L | D1.5R0.2*6H*4D*50L |

| D0.5*1H*4D*50L | D0.8R0.4*2H*4D*50L | D1.5R0.2*8/10/12H*4D*50L |

| D0.5*1H*2/3/4/6/8/10L*4D*50L | D0.8R0.4*1.6H*2/3/4/6L*4D*50L | D2R0.1*6H*4D*50L |

| D0.6*1.2H*4D*50L | D1R0.5*3H*4D*50L | D2R0.1*5H*8/10/12L*4D*50L |

| D0.6*1.2H*2/3/4/5/6L*4D*50L | D1R0.5*2H*4D*50L | D2R0.2*6H*4D*50L |

| D0.8*1.6H*4/5/6L*4D*50L | D1R0.5*2H*3/4/5/6/8/10L*4D*50L | D2R0.2*5H*8/10/12/16L*4D*50L |

| D0.8*1.6H*4D*50L | D1.5R0.75*3H*4D*50L | D3R0.2*9H*3D*50L |

| D1.0*4H*4D*50L | D1.5R0.75*3H*5/6/8/10L*4D*50L | D3R0.2*9H*4D*50L |

| D1.0*2.5H*6/8/10/12/16L*4D*50L | D2R1*4H*4D*50L | D3R0.3*9H*3D*50L |

| D1.5*6H*4D*50L | D2R1*4H*6/8/10/12L/16L*4D*50L | D3R0.5*9H*3D*50L |

| D1.5*3.75H*8/10/12/16L*4D*50L | D3R1.5*6H*3D*50L | D3R0.5*9H*4D*50L |

| D2.0*6H*4D*50L | D3R1.5*6H*4D*50L | D4R0.2*12H*4D*50L |

| D2.0*5H*8/10/12/16L*4D*50L | D3R1.5*6H*8/10/12L*4D*50L | D4R0.5*12H*4D*50L |

| D2.5*7.5H*4D*50L | D4R2*8H*4D*50L | D6R0.2*18H*6D*50L |

| D3.0*9H*3D*50L | D4R2*8H*4D*75L | D6R0.2*18H*6D*75L |

| D3.0*9H*4D*50L | D5R2.5*10H*6D*50L | D6R0.5*18H*6D*50L |

| D4.0*12H*4D*50L | D6R3*12H*6D*50L | D6R0.5*18H*6D*75L |

| D4.0*12H*4D*75L | D6R3*12H*6D*75L | D8R0.5*24H*8D*60L |

| D5.0*15H*6D*50L | D6R3*12H*6D*100L | D8R0.5*24H*8D*75L |

| D6.0*18H*6D*50L | D8R4*16H*8D*60L | D10R0.5*30H*10D*75L |

| D6.0*18H*6D*75L | D8R4*16H*8D*75L | D10R0.5*30H*10D*100L |

| D6.0*18H*6D*100L | D8R4*16H*8D*100L | |

| D8.0*24H*8D*60L | D10R5*20H*10D*75L | |

| D8.0*24H*8D*75L | D10R5*20H*10D*100L | |

| D8.0*24H*8D*100L | ||

| D10*30H*10D*75L | ||

| D10*30H*10D*100L | ||

Instructions:

1. Before using the carbide end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the carbide extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

3. In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide end mill.

5. Note: Not suitable for low speed machines such as rotary table and electric hand drill.

Applications:

Copper Electrodes, Copper, and so on. General-purpose operation of milling, rolling, profiling.