Celebrating the 76th anniversary of the founding of the People’s Republic of China and the Mid Autumn Festival!

Wishing all Chinese around the world a happy holiday!

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

~Abandoning the complexity of multiple cutting tools, only one milling tool is needed to improve aluminum material processing~

The automotive industry is facing a dilemma regarding “weight”. For example, the so-called light vehicles produced in the United States in 2017 had an average weight of 4044 pounds – so they don’t always live up to their name. New components and technologies have increased the weight of vehicles, but at the same time, environmental considerations require manufacturers to find ways to reduce weight. As a lightweight material, aluminum metal can solve this problem, but its milling and processing face challenges. In this article, Eduardo Debone, the global manager of Sandvik Coromant Automotive, a leading global metal cutting company, explains how to overcome difficulties with a single process milling cutter.

Aluminum metal will always be regarded as a material that can ‘fulfill the dream of flying’. The application of aluminum materials in the aviation field even predates the birth of the first aircraft in the late 1800s, namely Count Ferdinand Zeppelin’s famous aluminum framed airship of the same name, the Zeppelin airship. The lightweight characteristics of aluminum materials have made them still popular to this day. For example, its application in automotive engines can help significantly reduce vehicle weight and save fuel

For example, in the field of transportation, the power system of a European passenger car typically contains approximately 80 kilograms of aluminum material, making components such as the engine and gearbox the preferred weight reduction measures. Given the increasing popularity of aluminum materials, machine tool manufacturers require specialized cutting tool solutions to make aluminum metal the preferred material for workpieces.

▲ Part complexity

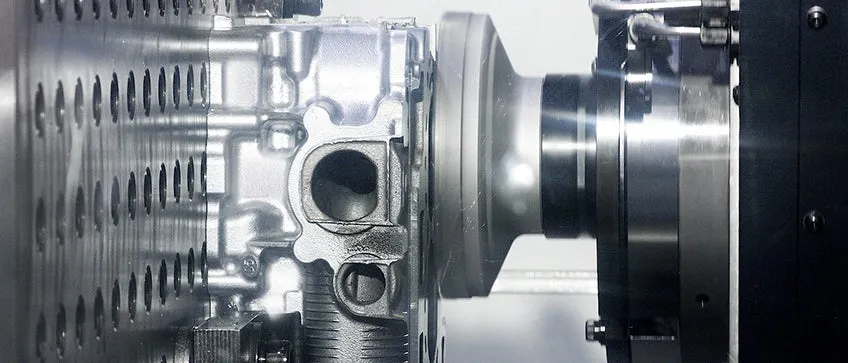

The cylinder block is the main component of a vehicle engine, responsible for accommodating several moving parts that work together to generate the power required for vehicle movement. For many years, cylinder blocks have been made of cast iron materials, but nowadays passenger cars generally choose aluminum alloy materials to reduce weight.

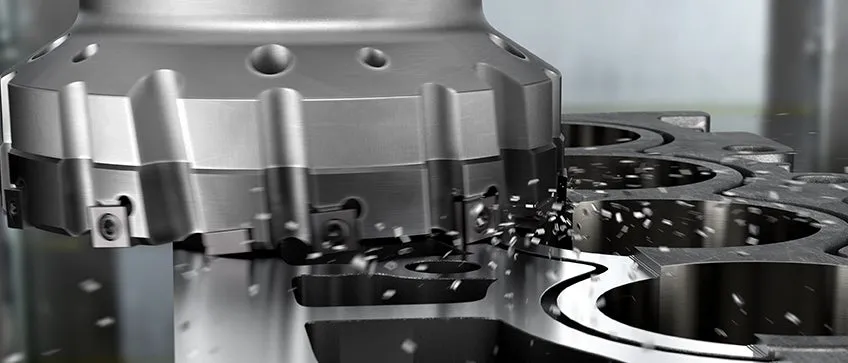

In the production of automotive parts, the manufacturing of cylinder blocks involves the largest number of machine tools, the process flow is often complex, and the allowable tolerance range is small. The rough and precision machining of some key and complex automotive components, such as cylinder blocks, is an expensive and time-consuming process. The entire process requires the use of several different cutting tools, which means an increase in the frequency of fixture adjustment and the need for more coolant to reduce the heat generated by increased friction.

The cylinder head of the engine is also a critical component, often made of aluminum material. The cylinder head is responsible for delivering air and fuel to the combustion chamber; Meanwhile, due to its location at the top of the cylinder block, it is also responsible for accommodating various components such as valves, spark plugs, and fuel injectors. Like the cylinder block, the cylinder head also requires complex and precise high-quality machining.

Indeed, aluminum material is lighter than cast iron material, but at the same time it is much softer. Therefore, poor surface quality of workpieces, the generation of burrs, and uneven tool wear are common phenomena. So, how can car manufacturers overcome these challenges, shorten production cycles, improve surface quality, and save costs.

▲ Single process solution with ‘one sequence in place.

As an expert in the field of metal cutting, Sandvik Coromant has discovered that the essence of innovation lies in simplicity. Replacing multiple cutting tools with a single process solution for surface milling can easily solve many difficult problems in aluminum material processing. The so-called single process solution uses multifunctional milling tools, which means that the same tool can provide both rough and precision machining capabilities, thereby reducing the cutting force on aluminum materials and achieving higher quality machining results.

Sandvik Coromant’s aluminum material processing solutions include several unique patented tool designs that enable fault free, precise, and burr free milling. This includes our M5C90 aluminum milling cutter, which belongs to the M5 product series and is specifically used for rough and fine surface milling of cylinder heads, cylinder blocks, and all aluminum components. It is recommended for large cutting width milling and is not suitable for thin-walled components. This tool can complete the entire process from rough machining to precision machining in one sequence.

It is crucial that the tool can complete the entire milling process from coarse to fine with just one pass, and in many cases, the milling depth can reach up to six millimeters. We have witnessed significant results: tool life has been extended by up to five times, and production cycles have been shortened by up to 200%.

A key feature of the M5 series cutting tools is their progressive technology. A series of precise and durable polycrystalline diamond (PCD) blades are arranged in a circular pattern, gradually and minimally removing workpiece materials layer by layer, including axial and radial directions. In addition, the last tooth of the tool is designed with a wiper polished blade to ensure excellent surface quality and flatness. The position of the wiper polishing blade and other blades is fixed, thus eliminating the complex and time-consuming tool adjustment process. Although the entire manufacturing process of an automotive aluminum component requires several cutting tools, this multifunctional solution frees the aluminum material from bearing a lot of cutting forces during the machining process.

As part of the ongoing pursuit of environmental performance in the automotive industry, selecting appropriate materials will become an indispensable part of vehicle weight reduction strategies. At the same time, tools such as M5C90 aluminum material milling cutters provide manufacturers with a simpler processing method that can meet various processing requirements for complex aluminum materials. From this perspective, perhaps aluminum materials can naturally become a good solution to the “weight” dilemma in the automotive industry.

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

FUJI Tools was founded in 1992 with a business policy dedicated to CNC machining center peripheral tools and cutting tools. In recent years, the company has invested more resources to establish a comprehensive operating environment and advanced manufacturing equipment in response to the cutting market demand, providing higher product quality and improved processing efficiency for mechanical processing industry workers.

Xingtan , Shunde ,Foshan City,Guangdong,China 528303

fujicn@jsh-fujitools.com

86-138 2276 9081