Celebrating the 76th anniversary of the founding of the People’s Republic of China and the Mid Autumn Festival!

Wishing all Chinese around the world a happy holiday!

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

Dry machining is one of the important development trends in future metal cutting, which refers to a machining method that does not use or uses very little cutting fluid during the machining process. Its core goal is to reduce the dependence on cutting fluid, lower production costs and environmental burdens, while improving machining efficiency.

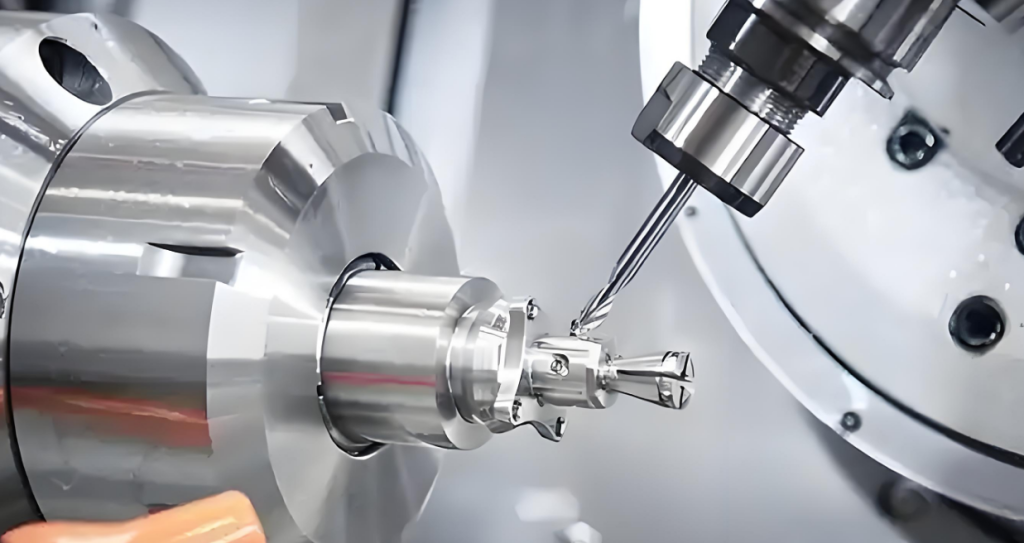

The key to this technology lies in tool design and material optimization. Cutting tools need to take into account geometric shape, high-temperature resistant materials, and coating technology: geometric shape needs to reduce friction and cutting heat to ensure smooth chip removal; The cutting tool material needs to have heat resistance and wear resistance, commonly using ultra-fine hard alloys, ceramics, etc; Coating technology reduces friction through insulation and solid lubrication, such as TiAIN coating, which is suitable for high-speed dry processing due to its strong oxidation resistance.

The development of dry processing stems from the emphasis on environmental protection and cost control needs of industrialized countries. The cost of cutting fluid treatment accounts for a relatively high proportion of the total cost of traditional machining, with statistics from the United States showing that it accounts for 14% -16%. Research has shown that if 20% of cutting is done using dry machining, the total cost can be reduced by 1.6%. With the advancement of high-temperature resistant materials and coating technology, dry processing has gradually become a feasible solution in the field of mechanical manufacturing.

One of the future trends in metal cutting: dry machining

Dry machining is one of the future trends in the development of metal cutting. In recent years, especially in industrialized countries, dry cutting has been highly valued. In order to implement environmental protection policies, efforts have been made to research, develop, and implement this new processing method. Cutting fluid plays a good role in reducing cutting temperature during operation, and is also beneficial for chip breaking and removal. However, there are also some problems, such as the use, storage, cleaning, and disposal of coolant, which are very complicated and costly. The harm of cutting fluid to the environment and the health of operators has always been limited in its use. The treatment of cutting fluid is also uneconomical, and these costs are often underestimated as they are included in indirect expenses. According to statistics from American companies, cutting fluid accounts for 14% -16% of the total cost in centralized coolant machining systems, while tool costs only account for 2% -4%. It is predicted that if 20% of cutting processes adopt dry machining, the total manufacturing cost can be reduced by 1.6%. Therefore, the future direction of machining is to use as little cutting fluid as possible, high-temperature resistant cutting materials and coatings, making dry machining possible in the field of mechanical manufacturing.

Tool Design

When designing cutting tools, it is always necessary to consider the balance between geometric shape, tool material, and coating, and it is impossible to use only the appropriate tool material for dry machining; Alternatively, only the coating method can transform traditional cutting tools into dry machining tools. In traditional cutting, various machining methods have different requirements for tool design. Dry machining tools must meet the following conditions: heat-resistant and wear-resistant tool materials, friction coefficient between chips and tools should be as small as possible, tool shape should ensure smooth chip removal, easy heat dissipation, high strength and impact toughness.

The design of dry machining tools must consider three aspects:

Coating. One of the reasons why cutting fluid can be omitted in today’s cutting process is coating, which reduces temperature shock by suppressing heat conduction from the cutting zone to the blade. Therefore, tool materials can be treated with coatings to achieve “solid lubrication” and reduce friction and adhesion. The tool absorbs less heat and can withstand higher cutting temperatures. Coatings have several functions in dry machining: isolating the tool from the cutting material, reducing friction, and insulation. Dry machining tools are usually coated and play an important role in tool performance. TiAIN coating has excellent heat resistance and high temperature performance. Compared with TiN and TiCN, the addition of AI greatly improves the anti-oxidation performance of cutting tools, making it very suitable for high-speed machining and dry machining. Its performance is four times better than TiC in high-temperature continuous cutting.

Geometric shape. Thermal effect is a fundamental issue in dry processing. When designing cutting tools, it is necessary to consider minimizing the possibility of heat generation at the beginning of machining, so cutting force and friction must be low. The additional problem with deep hole machining tools is that it is difficult to remove chips, so tool design must ensure a good chip removal effect. In the case of very low machining force, the design principle is to have a large rake angle and a large roundness cutting angle.

Tool material. The most important aspect of cutting materials during dry machining is high temperature resistance. If a large front angle is necessary, high hardness is also necessary. At present, the tool materials suitable for dry machining include ultrafine particle hard alloys CBN、PCD、 Ceramics and metal ceramics, etc.

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

FUJI Tools was founded in 1992 with a business policy dedicated to CNC machining center peripheral tools and cutting tools. In recent years, the company has invested more resources to establish a comprehensive operating environment and advanced manufacturing equipment in response to the cutting market demand, providing higher product quality and improved processing efficiency for mechanical processing industry workers.

Xingtan , Shunde ,Foshan City,Guangdong,China 528303

fujicn@jsh-fujitools.com

86-138 2276 9081