Celebrating the 76th anniversary of the founding of the People’s Republic of China and the Mid Autumn Festival!

Wishing all Chinese around the world a happy holiday!

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

01 Advantages of Ceramic Blades

Hard alloy cutting tools encounter challenges when processing HRSA high-temperature alloys, and ceramic blade materials have become a powerful alternative. Whether it is turning or milling high-temperature alloys, Sialon and whisker reinforced ceramics have demonstrated their excellent applicability. It is worth mentioning that these ceramic materials perform particularly well when facing high-temperature materials such as Inconel alloy, which is commonly used in high-temperature environments for aircraft engines and energy production.

◇ Differences between milling and turning

Although ceramic materials have strong thermal hardening and low reactivity to workpiece materials, their strength and toughness are relatively low. Therefore, high rigidity methods are required during the processing to reduce vibration. In order to ensure the machining effect, the tool overhang should be minimized as much as possible, and the smooth insertion and retraction of the tool should be ensured. Meanwhile, full groove milling should be avoided during milling to fully utilize the advantages of ceramic materials.

Compared with ceramic turning, milling process presents some significant differences. When turning, the cutting speed is usually controlled within about 300 m/min; The speed of milling tools may be as high as 1000 m/min. In addition, ceramic turning requires continuous and high flow of coolant to dissipate heat; During the milling process, in order to avoid thermal stress, there is no need to use coolant at all.

◇ High productivity of ceramic milling

When choosing cutting tools, circular inserts are the ideal choice for turning and milling ceramics. To reduce groove wear, it is recommended to use a lower cutting depth and achieve a small main deviation angle. Meanwhile, during the milling process, a relatively low feed rate (compared to hard alloys) should be followed to achieve higher cutting speeds. In this way, the high temperature generated around the cutting area will enhance the cutting effect and promote the efficient removal of hot small chips. In addition, surface milling performs better in ceramic milling compared to edge milling and waterline milling.

The use of ceramics for milling, especially in the application of ISO S materials in aerospace engines, has demonstrated significant high productivity advantages. During the milling process, it is recommended to use forward milling for positive rake angle inserts, while reverse milling is suitable for negative rake angle slots. However, it should be noted that reverse milling may result in thick chips at the outlet. Through a series of optimization measures, the maximum speed capability of ceramic cutting tools has been significantly improved, thus meeting the high requirements for metal removal rate in harsh HRSA high-temperature alloy applications.

02 Milling parameter optimization

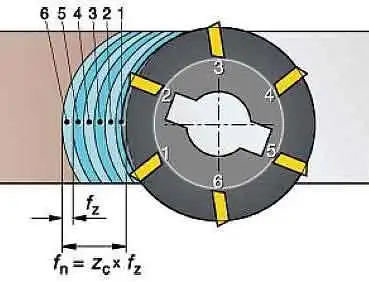

Reasonable feed rate per tooth is crucial for improving productivity and ensuring machining quality during the milling process.

◇ The importance of feed rate per tooth

In milling, the selection of feed rate per tooth is crucial. It not only affects processing efficiency, but also has a profound impact on processing quality. We must carefully choose the feed rate for each tooth based on different processing materials and specific requirements to ensure the smooth progress of the machining process. By optimizing tool design and cutting parameters, we can achieve efficient milling to meet the demanding application requirements of high-end fields such as aerospace engines.

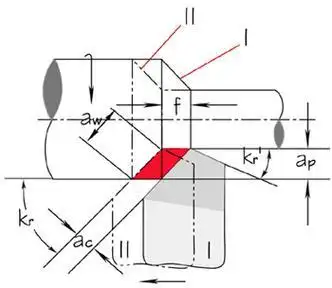

◇ Workbench provides cutting depth

In the milling process, the feed rate (vf, in mm/min) of the worktable is an important parameter. Usually, it can be adjusted within the range of 600 to 2000mm/min, and the specific value depends on various factors such as the processing material, tool type, and required processing quality. Meanwhile, the cutting depth (ap, in millimeters) is also one of the key factors affecting the machining effect. By adjusting these parameters reasonably, we can achieve efficient and high-quality milling processing.

◇ Performance comparison and benefits

In milling operations, the feed rate of the worktable is interrelated with the cutting depth. The feed rate determines the distance that the tool moves per unit time, while the cutting depth reflects the depth at which the tool cuts into the workpiece during each cutting. These two factors jointly affect the efficiency and accuracy of processing. By reasonably matching the feed rate and cutting depth, we can achieve ideal machining results.

In the milling process, cutting width is a key parameter. When the cutting width is 1.5mm, we observed a significant increase in metal removal rate, from the original 19.3cm ³/min to 132.3cm ³/min. This improvement has brought significant benefits, saving a total of 42 hours of cutting time per year and increasing productivity by up to 469%. This result fully demonstrates the importance of optimizing cutting width in improving machining efficiency and saving time.

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

FUJI Tools was founded in 1992 with a business policy dedicated to CNC machining center peripheral tools and cutting tools. In recent years, the company has invested more resources to establish a comprehensive operating environment and advanced manufacturing equipment in response to the cutting market demand, providing higher product quality and improved processing efficiency for mechanical processing industry workers.

Xingtan , Shunde ,Foshan City,Guangdong,China 528303

fujicn@jsh-fujitools.com

86-138 2276 9081