One of the future trends in metal cutting: dry machining

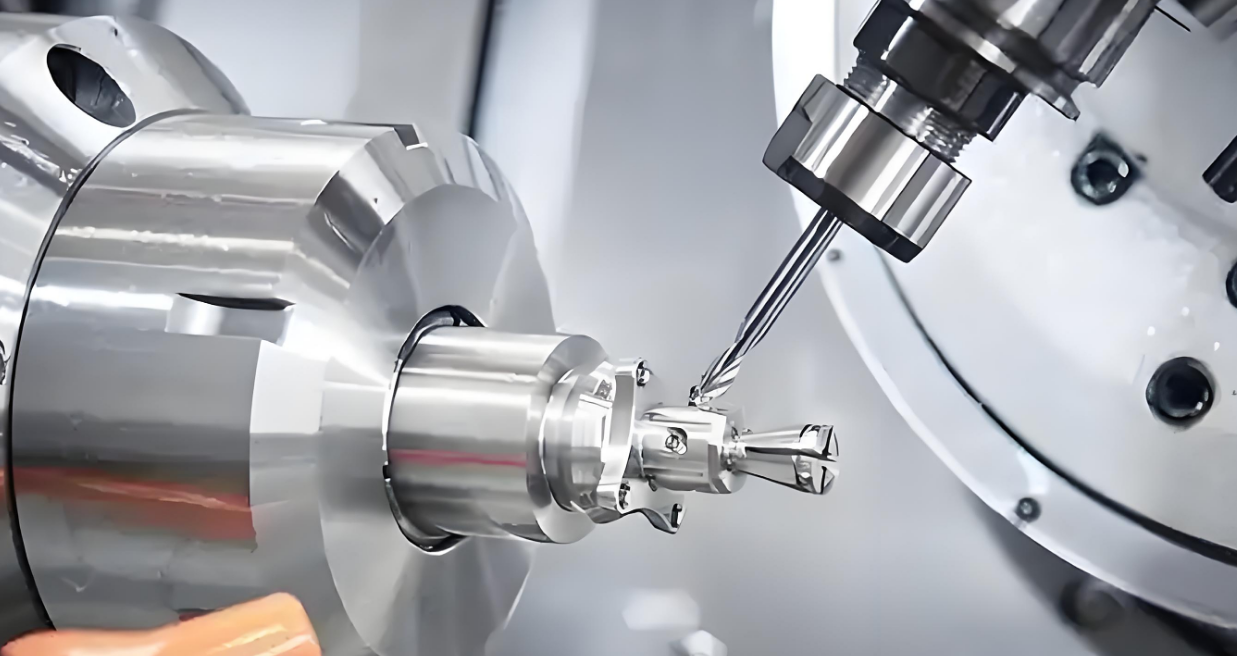

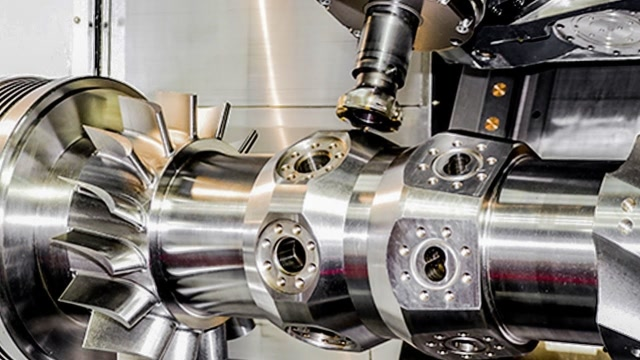

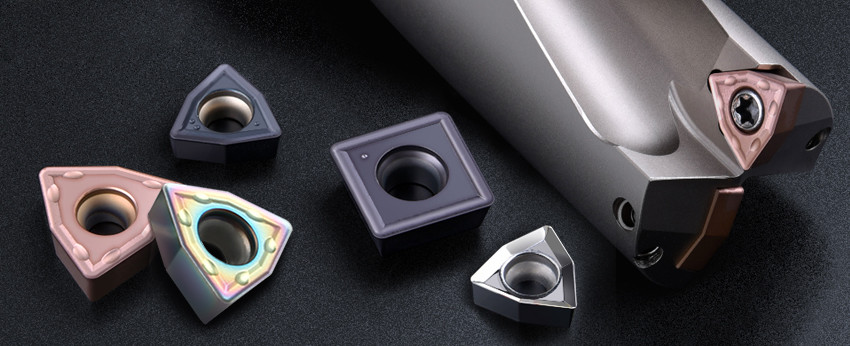

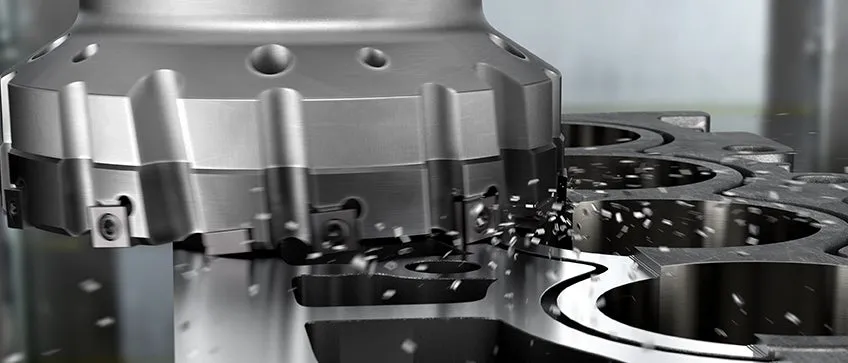

Dry machining is one of the important development trends in future metal cutting, which refers to a machining method that does not use or uses very little cutting fluid during the machining process. Its core goal is to reduce the dependence on cutting fluid, lower production costs and environmental burdens, while improving machining efficiency.The key … Read more