Celebrating the 76th anniversary of the founding of the People’s Republic of China and the Mid Autumn Festival!

Wishing all Chinese around the world a happy holiday!

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

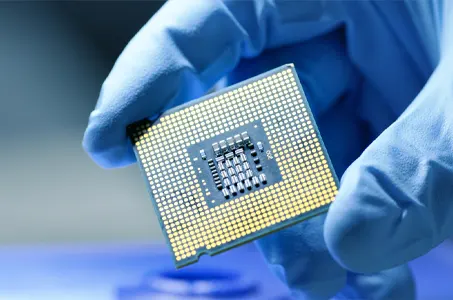

1.Technical challenges of cutting tools in the semiconductor industry:

1)Breakthrough in material processing limits

The hardness of third-generation semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) is close to that of diamond (Mohs hardness 9.5), and the wear rate of traditional hard alloy cutting tools is as high as 80% or more. It is necessary to rely on polycrystalline diamond (PCD) or metal ceramic cutting tools to achieve efficient machining

Wafer cutting requires controlling the edge breakage rate to be less than 1 μ m, while inner circle cutting machines are prone to surface damage of over 50 μ m due to the coarse diamond particles (28-53 μ m), requiring the development of ultrafine grain (<700nm) cutting tools.

2) Accuracy and stability requirements

The width of the 12 inch wafer cutting track should be controlled within 30-50 μ m, and the tool thickness error should be within ± 1 μ m. The metal ceramic blade can reduce the vibration amplitude by 60% through anti vibration design

The packaging process needs to deal with chemical corrosion (such as lead frame cutting), and the corrosion resistance of metal ceramic cutting tools needs to reach more than 5 times that of ordinary hard alloys

2.Local advantages and innovative solutions

Wishing all Chinese around the world a happy holiday!

01 Advantages of Ceramic BladesHard alloy cutting tools encounter...

Dry machining is one of the important development trends...

~Abandoning the complexity of multiple cutting tools, only one...

FUJI Tools was founded in 1992 with a business policy dedicated to CNC machining center peripheral tools and cutting tools. In recent years, the company has invested more resources to establish a comprehensive operating environment and advanced manufacturing equipment in response to the cutting market demand, providing higher product quality and improved processing efficiency for mechanical processing industry workers.

Xingtan , Shunde ,Foshan City,Guangdong,China 528303

fujicn@jsh-fujitools.com

86-138 2276 9081